Anni Hamari, M.Sc. (Tech.), project engineer, New Industry, Lapland University of Applied Sciences

Katri Hendriksson, M.Eng., project manager, New Industry, Lapland University of Applied Sciences

Hanna-Mari Romakkaniemi, Bachelor of Natural Resources, Agronomist, project planner, Future Bioeconomy, Lapland University of Applied Sciences

Henri Saarela, M.Sc. (Tech.), project engineer, New Industry, Lapland University of Applied Sciences

Thinking in circles

The circular economy thinking begins with an insight. Unless circular economy is explained in a way that is understandable, people may think it equals just recycling. Sea Lapland’s Resource Intelligence project challenges the region to think in cycles. Inside different business or operating models, regardless if it is in the field of food or construction industry, every process and even the smallest particle of resource has its own life cycle. Every operator binds various resources into several kinds of service or product processes. Resources can be natural resources, raw materials, energy, space, time and even know-how. Resource intelligence is the ability to utilize these versatile resources with great wisdom in different kind of life cycle phases, while promoting sustainable development and wellbeing in the same time. Instead of just recycling or minimizing waste in the end of the life cycle, resource intelligence is also associated with design, marketing, operating, trade, distribution and other phases.

The aim of the Lapland University of Applied Sciences’ project called SERI – Sea Lapland’s resource intelligence (picture 1.) has been to develop the low-carbon and resource intelligence in Sea-Lapland’s area. The operating period of the project is from 1.1.2020 to 31.12.2021. The total budget of the project funding is 353 690 € where the ERDF funding granted by the Lapland Association accounts is 282 952 €. (Lapland University of Applied Sciences 2021)

Picture 1. SERI – Sea-Lapland’s Resource Intelligence -project.

Side streams are utilized in the CE

Primary production forms a lot of different side streams including animal manure, which is exploited in the production of new crops, and as a result of feed storage, bale and Fodder stack plastics, which are exploited for thermal energy. Also, the food industry forms a lot of different side streams, such as the trade industry, where the formation is affected by various things than in the domestic kitchen or primary production. Equal to the resulting side streams is that often they are waste at their birthplace, but with the right fractionation and refining it is possible to generate new and higher value products than what the waste is in the place of birth. Regrettably often the side stream is considered waste. However, it should first be aware of when the side current can be exploited and in what way. Regardless of the industry sector, there are alternative exploitation channels and customs for almost all side stream without “waste status”. This often means an increase in information to learn how to identify when the resulting side stream can be produced into a higher value product. Seeking a suitable collaborator elsewhere may be easier and more cost-effective if the other option is investing construction of its own processing unit. (Opetushallitus 2020)

In Finland and Sea Lapland region are very strong agricultural areas, that are also well suited to farming in climate conditions. Sea-Lapland’s strong agricultural expertise and conditions are a success factor for a large number of good, nutritious and yielding berry species and varieties. Some of them are also grown commercially in the area and almost all successful berry species are cultivated in home gardens. Encouraging home-grown farming and securing it by diversifying varieties is almost a lifeline to maintaining the vibrancy of the countryside and keeping the sparsely populated countryside. Rural viability and well-being people also create local culture and activities by keeping the villages alive and functioning. (Saariniemi 2021)

SERI — Sea Lapland’s resource intelligence project implemented a package of materials in support of berry cultivation and growing/breeding, which highlights more information on the requirements of six different species of berries and the conditions for the success of cultivating the species in the North Finland. In addition, varieties require frequent thick snow cover to succeed, which is achieved in the Sea-Lapland region practically every winter. The success and introduction of such berry plant species into Finland can also help in the challenging position countryside to gain more livelihood enabling production. Through carbon emissions should also be considered the regional economic impact of local production and low carbon production, with significant savings from the cost of transport of products as transportation journeys become shorter. (Saariniemi 2021)

There is also a need for new and pre-existing unknown species in order to maintain the interest of farmers in primary production. Consumers also crave new and special species and products for their home kitchens. It is therefore important that we also find faith and dare in Sea-Lapland to try and promote the cultivation and production of rarer berry plants in Finland. The next step to concretizing the data collected in the material package would be crop trials, both in home gardens and commercial production. Knowledge and skilled research staff can be found both at the University of Lapland, Lapland UAS, Lappia Vocational College and Lappia-Education Ltd, and also Lapland Education Center REDU and REDU-Edu Ltd. (Saariniemi 2021)

Resource intelligence in the marketing phase

Resource intelligence in marketing appears apparently in two ways: either it’s possible to market your business models resource intelligent or apply the resource intelligence in your business’ marketing operations. It’s not a shame to use little resources, instead, it is recommended to even emphasize it. According to the second method resource intelligence in marketing includes identifying and analyzing the most effective channels to focus resources into. Many micro and small businesses don’t have separate marketing person or marketing department, not to mention separate marketing expertise.

It may lead to situation, where marketing is misleading, outdated or it does not exist. Marketing doesn’t necessarily use any materials, especially when it is digital marketing. Marketing still uses different kinds of resources of the operator, for example, time and know-how.

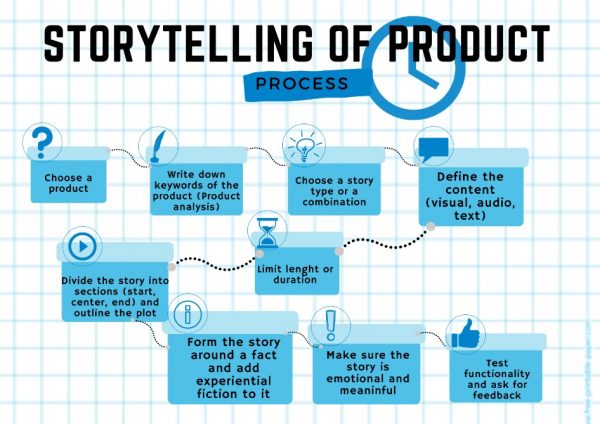

Storytelling in marketing purposes can increase sales of products or services. Economic growth is part of the circular economy as much as in the linear economy, but in the CE growth is ideally accomplished non-materially. In picture 2, there is depicted how to create a story for a product in a simply way.

Picture 2. Process of storytelling of product (Picture: Anni Hamari)

Carbon footprint calculations: the first step to a low carbon future

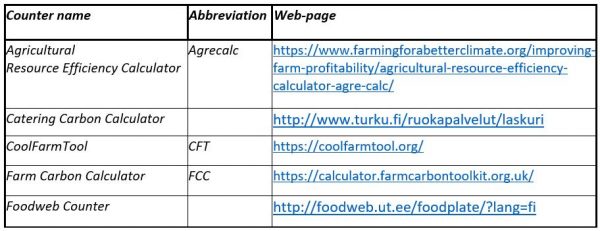

Carbon dioxide emissions don’t straight correlate with circular economy and its progression, but the term “a carbon-neutral circular economy” is a breakthrough because of climate change. Besides, the circular economy is commonly understood to tackle climate change. Every operator should at least know their relation on the carbon dioxide emissions in different emission scopes; either in relative way or in concrete numbers. First step of action is to calculate the carbon footprint of a product, a department, or a whole business. Finnish Environment Institute (Finnish Environment Institute & City of Turku 2019) has developed a calculator for catering operators which is also Sea Lapland’s Resource Intelligence project’s recommendation for calculations in the catering business area. The project applied the calculator in a catering area pilot. However, the pilot also used a Foodweb counter (Foodweb 2021) to calculate greenhouse gas emissions from food. Another field in the food industry is a crop production and the project discussed a lot about its carbon footprint which is a challenging and newly discovered topic in itself. The project worked with this topic in one different pilot and has three alternative recommendations for carbon footprint calculators in the field of agriculture: Farm Carbon Calculator (FCC), Cool Farm Tool and Agricultural Resource Efficiency Calculator (Agrecalc). Table 1 shows more carbon footprint counters.

Table 1. Carbon footprint counters

Resource intelligence and circular economy at construction and deconstruction business

In construction business there are many viewpoints for resource intelligence. Planning buildings with resource intelligence includes for example efficient energy and material solutions, maintainability, repairability, transformability and capability to recycle construction materials. (Kirkinen 2013) A building constructed in resource intelligence way is ecological, smart and appropriate for its users. (Sitra 2016) In deconstruction business recycling demolition materials efficiently is an essential way to improve resource intelligence and circular economy.

Circular economy is one essential part of resource intelligence both on construction and deconstruction business that are linked strongly each other in this case. The most common demolition materials (concrete, brick, plaster, wood, metal, glass, roofing felt, plastic, asphalt, insulating material, soil material) can be used many different ways to new purposes: best solution would be using as such without time and energy wasting by modifying material (Lehtonen 2019). Doors and windows are probably the most obvious example that can be used as such, but sometimes construction product legislation may restrict usage e.g. of old windows in new buildings (Lahti 2019). And in Denmark there has been used brick elements from old, deconstructed buildings to construct wall prefabs to new buildings. (Wilson 2019) That is circular economy at its purest form in bigger scale. Second best option is to use materials after they have been processed somehow: metals typically have the best recycling rate (demolition metals are melted and used as raw material in new metal making process) of all demolition materials and often metals are the only material that can be actually sold for its utilizer.

Resource intelligence: case waste concrete

Concrete is the most used construction material in the world. Global production of concrete is about 13 billion cubic meters annually. (Betoni 2021) Producing cement that is one of the main raw material of concrete causes 5-8 % of all greenhouse gases globally (Savela 2019). So, it is obvious that there is a real need for utilizing concrete waste smartly and sustainable way.

Traditionally concrete waste has been used mainly (crushed) at earthworks or infrastructure construction and it is quite often, depending on its quality and the number of contaminants, very suitable for those purposes. Another suitable way to utilize concrete waste is to use it as a raw material to partly replace natural stone granule in production of new concrete. (Lehtonen 2019) In Finland this way to use concrete waste is at the moment quite uncommon mainly due to high qualifications in bureaucracy and legislation. Though, this will hopefully change in near future: the ministry of environment of Finland has been preparing an End of Waste -regulation for concrete waste to lower the restrictions of its broader usage e.g. as a raw material in producing new concrete (Ympäristöministeriö 2019). Regulation is about to come into effect in autumn 2021 (Ympäristöministeriö 2021). For example Germany has had very good experiences of using recycling-based concrete in which part of the natural stone granule is replaced with waste concrete. Actually, the state of Berlin requires using this kind of concrete in public high-rise construction projects. (Asp 2020)

Special features of resource intelligence of construction and deconstruction business in Lapland

Lapland is generally a sparsely populated area with long distances: Lapland covers almost one third of the area of Finland but only 3 % of the total population of Finland live in Lapland (Ympäristöhallinto 2019). This causes special features, challenges and opportunities in what comes to creating resource intelligence in the area.

There are materials that can be recycled by using them as raw material in some process: e.g. roofing felt contains bitumen and can be utilized as raw material in asphalt making process where it can substitute virgin bitumen. This provides both economic and ecological benefits. But when the distances are long the transport costs and emissions increase so much that is not worth to transport materials to be recycled if the distance is long. Therefore, in Lapland we need to be innovative and strongly co-operate in order to be able to utilize demolition materials in resource intelligent way. There have been pilots in Finland where cities have provided residents an opportunity to pick up materials and movables from buildings to be deconstructed. Municipalities and cities could have more communication with each other and with companies: e.g. if there is starting a construction project it would be beneficial to map whether there would be nearby demolition waste material for to be utilized. Summary: acting resource intelligent is possible also here in Lapland but often requires some extra activity.

How the pilots have promoted resource intelligence in the Sea Lapland region?

The SERI – Sea Lapland’s Resource Intelligence project carried out by Lapland University of Applied Sciences has implemented several pilots during the project and the themes were connected to the areas of circular economy and resource intelligence. The pilots were carried out e.g. related to reducing the carbon footprint, increasing the utilization rate of local food, raising awareness of construction resource intelligence and more effectively marketing a company’s product or service.

Resource intelligence can be viewed from many different perspectives and the SERI project wanted to take part in this so that all the various solutions and alternatives could come to the fore. The pilots implemented by the SERI project have brought new perspectives to the Sea Lapland’s region to implement a circular economy and resource intelligence. The aim of this project was to support actors in this region and help them to look at their own activities in terms of the development resource intelligence.

The pilot measures implemented by the SERI project have increased the visibility of the Sea-Lapland’s region. As the region operates more circularity and make more actions to resource intelligence the region’s reputation can be raised effectively. Thanks to the measures and circularity actions by this project, the by-products in the Sea Lapland’s region can be utilized much better.

Sources

Asp, E. 2020. Uusiobetonin käyttö rakentamisessa. Tampereen yliopisto, rakennustekniikka. Referred 9.9.2021 https://trepo.tuni.fi/bitstream/handle/10024/119173/AspEmmi.pdf?sequence=2&isAllowed=y

Betoni. 2021. Betoni rakennusmateriaalina. Betoni.com. Referred 30.9.2021 https://betoni.com/tietoa-betonista/perustietopaketti/betoni-rakennusmateriaalina/

Kirkinen, J. 2013. Kohti resurssiviisautta. Sitra. Referred 9.9.2021 https://docplayer.fi/10333656-Resurssiviisaus-rakentamisessa-tkt-johanna-kirkinen-sitra.html

Lahti, J. 2019. Purkumateriaalien jatkokäsittelyvaihtoehdot. Tulevaisuuden kiertotalouskeskukset CircHubs -hanke. Referred 9.9.2021 https://ekokumppa-nit.fi/wp-content/uploads/cicrhubs-purkumateriaalien-jatkokasittelyvaihtoehdot.pdf

Lapland University of Applied Sciences. 2021. On-going projects. Projects – Lapland UAS (lapinamk.fi)

Lehtonen, K. 2019. Purkutyöt -Opas tekijöille ja teettäjille. Ympäristöministeriö. Refered 30.9.2021 https://julkaisut.valtioneuvosto.fi/bitstream/handle/10024/161884/YM_2019_29.pdf?sequence=4&isAllowed=y

Opetushallitus. 2020. Ilmasto-osaamisen kartta; maatalous, elintarviketeollisuus, ruoka. Referred 6.9.2021. https://www.oph.fi/sites/default/files/documents/osaamiskartta_-maatalous_elintarviketeollisuus_ruoka_1.pdf

Saariniemi, J. 2021. Talking 22.3.2021. Author’s own notes.

Savela, S. 2019. Betoni tuottaa enemmän ilmastopäästöjä kuin lentoliikenne – pikkuinen firma Kannonkoskelta aikoo romauttaa päästöt tekemällä betonin jätteistä. Yle. Referred 30.9.2021 https://yle.fi/uutiset/3-10816632

Sitra. 2016. Resurssiviisas rakentaminen. Referred 9.9.2021 Resurssiviisas rakentaminen – Sitra

Wilson, R. 2019. Old into new: Recycled bricks form façade of Copenhagen housing project. Architect’s Journal. Referred 9.9.2021 https://www.architectsjournal.co.uk/buildings/old-into-new-recycled-bricks-form-facade-of-copenhagen-housing-project

Ympäristöhallinto. 2019. Yhdyskuntarakenne – Lappi. Ympäristöhallinto. Referred 9.9.2021 https://www.ymparisto.fi/fi-FI/Elinymparisto_ja_kaavoitus/Yhdyskuntarakenne/Yhdyskuntarakenne__Lappi(28061)

Ympäristöministeriö. 2019. Valtioneuvoston asetus arviointiperusteista sen määrittämiseksi milloin betonimurske lakkaa olemasta jätettä. Ympäristöministeriö. Referred 9.9.2021 https://ym.fi/hankesivu?tunnus=YM034:00/2018

Ympäristöministeriö. 2021. Ympäristöministeriön keskeisten lainsäädäntöhankkeiden ohjelma. Ympäristöministeriö. https://ym.fi/documents/1410903/38678498/ymparistoministerion-lainsaadantoohjelma-13-04-2021.pdf/

Key words: RDI, Circular Economy, Resource Intelligence, Sustainable development