Ferenc Kádár, Msc Eng, Project Engineer, Smart Build Environments, Lapland University of Applied Sciences

Introduction. Sustainable building material for tall buildings

The price of wood-based construction products rose exponentially in the first half-year of 2021. There is a real need to use renewable, reusable, and recyclable innovative materials and solutions. With carbon being captured in the wood, the wood building products offer a really sustainable solution of combating climate change. (Stora Enso 2021)

The innovative engineered wood product, the CLT (cross-laminated timber) has been successfully used in different solutions for residential, commercial, and industrial buildings. To facilitate the right construction, application, and usage of engineered wood buildings need more help from reasarch organizations.

Tallwood project and responsibilities

Tallwood is an Interreg Nord founded project supporting wood as a multistorey building material. The project started in 2019 and will end in 2022. The Tallwood project studies cross-border experiences and expertise in high wood buildings with the goal to develop innovative solutions on how to use wooden structural elements in multi-storey buildings. Furthermore, by increasing the utilization of wood in developing cost-effective wooden solutions in tall buildings, carbon dioxide emissions and the environmental impact of buildings will be reduced. In the Tallwood project, the Lapland University of Applied Sciences is responsible for work package 7 (WP7), with the main focus on the research and monitoring of tall wood buildings. (OAMK 2021)

Organizations involved in the project are from the northernmost parts of Finland, Sweden, and Norway. The project members are the following partners: Oulu University of Applied Sciences, Finland (OUAS) – project leader; Luleå University of Applied Sciences, Sweden (LTU); Research Institutes of Sweden (RISE); Nordland Research Institute, Norway (NRI); Lappia and Lapland University of Applied Sciences, Finland (LaplandUAS). (OAMK 2021)

DAS Kelo demonstration building

The LaplandUAS pilot project is the DAS Kelo, Rovaniemi. DAS Kelo is an eight-storey student apartment building with a CLT structure, the first storey being made of concrete. The adopted CLT modular building systems and prefabricated offsite construction method enabled a fast construction program and dramatically reduced labor costs. The Domus Arctica Foundation (DAS) was founded in Rovaniemi, with the aim of developing environmentally friendly building solutions for healthy residential buildings for students. DAS Kelo acts as a demonstration building in the Tall Wood project and LaplandUAS is researching it. For monitoring and collecting data, new-generation IoT sensors are used.

Picture 1. DAS Kelo student apartment building 2021 February, Kádár Ferenc LaplandUAS

After the construction work was finished, students moved into the building on the 1st of August, 2019. The building project is considered to be a successful promoter of wood construction in Lapland. (Puuinfo 2021)

Wireless IoT wood moisture sensor for measuring wood moisture content and the ambient humidity and temperature; Installation of the IoT sensors

Wood is a hygroscopic material that absorbs water. The building-material’s moisture content has a big importance regarding the technical properties of it. The control of humidity of wood elements and ensuring to keep it dry enough is vital from the production of a building material until the end of life of the building. The IoT sensors can be installed in the factory, so that the builders can see the moisture levels whole-time, from production to construction site, as well as during the construction and usage phase.

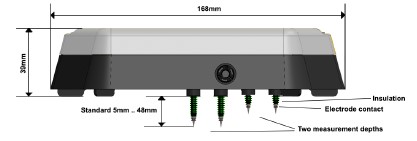

The IoT wood moisture sensor is intended for measuring the wood moisture content of wood construction elements with 2 depths as well as the humidity and temperature of the surrounding environment.

The Wiiste WM1-WAN IoT sensor is a Finnish new-generation sensor installed on the surface of wooden structures, for example CLT, LVL, or other wood elements in construction sites.

Picture 2. Components of Wiiste sensor, (Wiiste 2020a)

Sensor features might include automatic alerts on temperature, wood moisture contents, ambient temperature, and battery charge. The device uses two individual electrode pairs to measure the wood moisture content on the basis of electrical resistance. Using these electrodes, the Wiiste sensor can be fixed onto wooden structures.

The length of the electrodes should be selected to meet the desired measurement length, enabling to measure the cross-sectional moisture distribution in the wood structure.

The browser-based web service scales for different terminal devices and its other features including filling, reporting and sharing data, and the planning of measurement on the basis of ground plans. (Wiiste 2020 a)

The device begins automatic measurement after startup, upon connection to a LoRa network. The IoT sensors automatically send measurement data (moisture content in the wood, ambient relative humidity and temperature) to a cloud service in real time, allowing remote monitoring of the wood-moisture and environment humidity and temperature. (Wiiste 2020 b)

In February 2021 for the DAS Kelo project, we installed two sensors in a sample apartment.

On the 8th floor in the sauna common space, we installed another two sensors with same specifications.

One sensor with measuring depths of 38 mm and 8 mm was fixed straigth onto wood. The other sensor was installed on gypsum board with same measuring depths, in order to study the effect of gypsum board on the wood’s hygrothermal properties.

Picture 3. Fixing the sensor directly onto the CLT in the DAS Kelo building, Pirttinen Valtteri LaplandUAS:

Using the electrodes the sensor was attached onto the wood ceiling.

Picture 4. Fixing the sensor to the CLT via Gypsum board in the DAS Kelo building, Kádár Ferenc LaplandUAS

Data collection for the DAS Kelo demonstration building

By using Wiiste sensors, the relative dryness or wetness in the middle of CLT wood elements can be mapped out, and the moisture problems can be identified. Simultaneously, thermal comfort in the building is also studied.

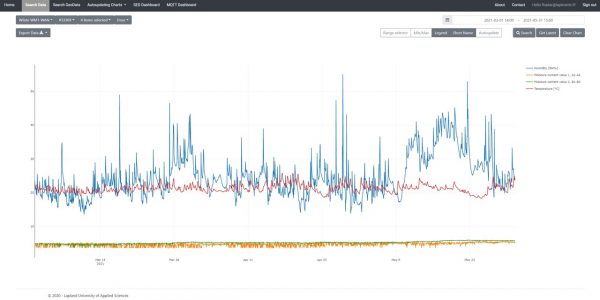

For a better visualization and to ensure comparison with other measured climate data, the data was transferred to the LaplandUAS Data browser.

Picture 5. Collected data by sensor attached straight onto the CLT in the examined apartment:

Collected data by sensor attached straight on the CLT in the examined apartment measuring CLT moisture, ambient relative humidity, and ambient temperature in the period 1.3.2021- 31.5.2021.

The moisture content in the depth of 38 mm (orange colour) varied between 3,70 – 5,90%, which was greater than the variation of 3,60 – 5,10% in the depth of 8 mm (green colour). This is because on the wood inner surface, the changes are of course faster and it acts as a moisture buffer when the indoor conditions change.

In the period 1.3.2021- 31.5.2021, the ambient temperature varied between 18-25 ̊ C an the ambiental relative humidity (RH% – blue colour) varied between 14-55 %. The lowest ambiental relative humidity value was recorded in 10.3.2021, when the outside temperature was low (-21 ̊ C).

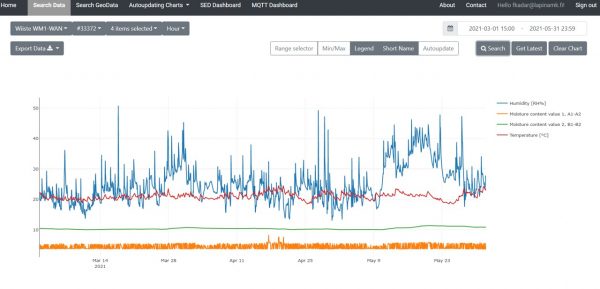

Picture 6. Collected data by sensor attached through gypsum board on the CLT in the examined apartment:

Collected data by sensor 2 in the examined apartment measuring CLT moisture through gypsum board, shows greater moisture content fluctuation of 3,60–8,90 % in the depth of 38 mm (orange colour), compared to the sensor attached straight onto the CLT.

In this case, the moisture content in the depth of 8 mm (green colour) varied between 9,90-11,40 %.

In the same period, the moisture content variation in the common sauna room is similar in the depth of 8 mm and 38 mm, in both cases (sensor attached straight and sensor attached through gypsum board on the CLT) shows similar fluctuation as in the apartment, but in the period 1.3.2021 – 31.5.2021, the ambient temperature varied between 19 – 30 ̊ C , while the ambient relative humidity has sunk below 10 % several times.

The reason for the higher temperature and humidity fluctuations is that the common sauna room is located on the top floor and therefore the humidity transport and the heat losses through the envelope are higher. At the same time, the internal heat gain is higher because of the sauna.

Our measurement started in March 2021 and we aim to continue for at least one year, until 2022. In addition to studying the variation of moisture content inside CLT structures, we study the thermal comfort in an apartment, and in sauna common space. Based on the observation and reports, we will provide recommendations for improving tall wood building constructions.

Sources:

Stora Enso. 2021.CLT- technical brochure. Accessed 4.8.2021 clt-by-stora-enso-technical-brochure-en.pdf (storaenso.com)

OAMK. 2021. TallWood – Supporting Wood as Multistory Building Material. Accessed 4.8.2021 https://www.oamk.fi/en/partnership/rdi-projects/tallwood

Puuinfo. 2020. DAS Kelo. Accessed 4.8.2021 https://puuinfo.fi/arkkitehtuuri/asuinkerrostalot/das-kelo/

Wiiste. 2020 a. WM1-WAN Product Data sheet.

Wiiste. 2020b. WM1-WAN Instruction for installation

Keywords: Wood construction, Tallwood, DAS Kelo, Wiiste sensors